Quality Control Failure Insurance in Battery Production: Protecting Your Manufacturing Investment

Understanding the Critical Need for Quality Control Failure Insurance in Battery Manufacturing

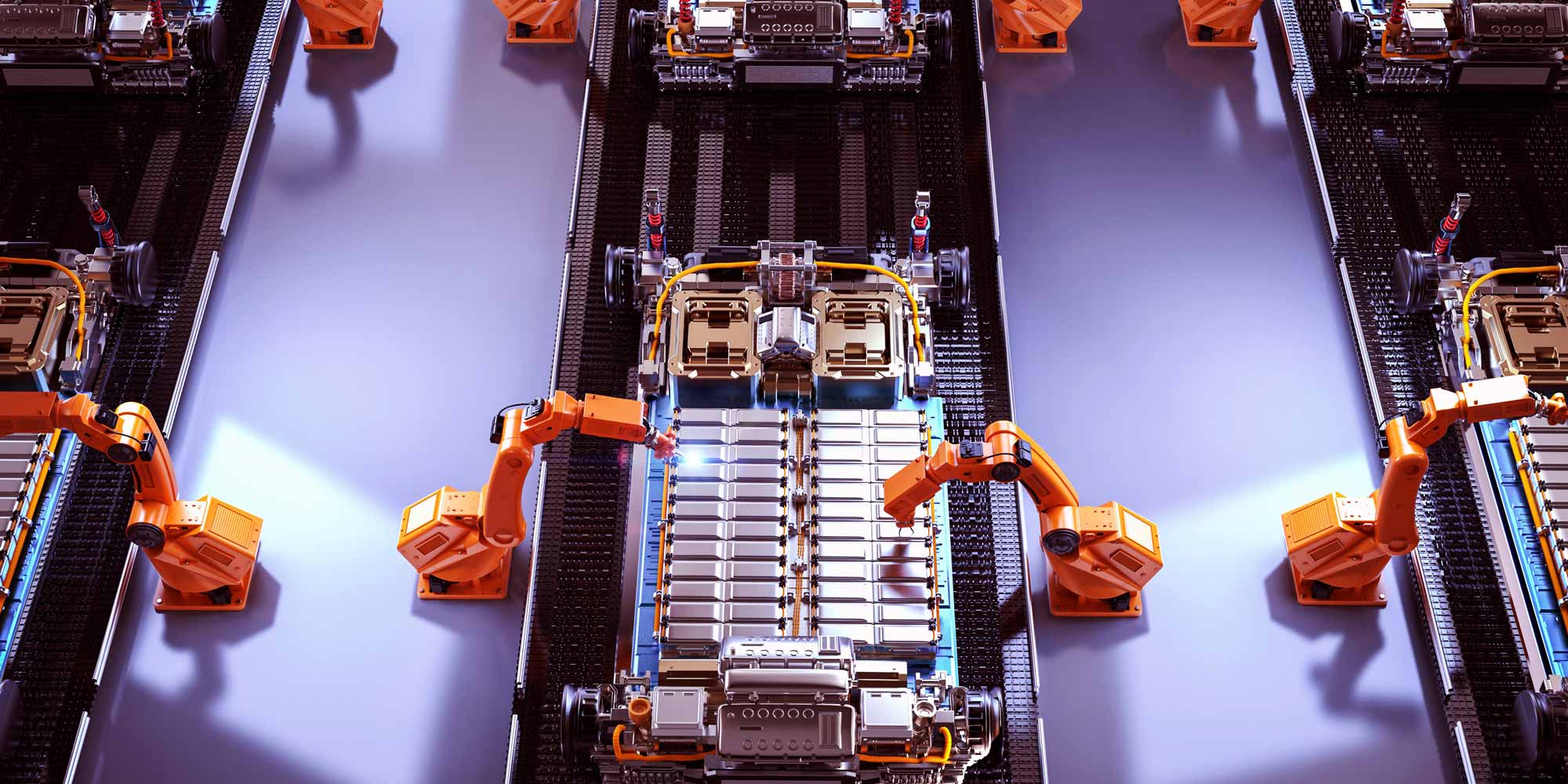

In the rapidly evolving world of battery production, where technological innovation meets stringent performance requirements, quality control failures can result in catastrophic financial and reputational consequences. This comprehensive guide explores the intricate landscape of quality control failure insurance, specifically tailored for battery manufacturers.

The Evolving Risk Landscape in Battery Manufacturing

Battery production represents a complex manufacturing ecosystem fraught with potential quality control challenges. From electric vehicle batteries to renewable energy storage systems, the stakes have never been higher.

Key Quality Control Risk Categories

- Material Defect Risks: Compromised raw material quality leading to battery performance degradation

- Manufacturing Process Risks: Inconsistent production techniques resulting in non-standard battery performance

- Performance Verification Risks: Inadequate testing protocols missing critical performance parameters

- Safety Compliance Risks: Failure to meet international safety standards and regulations

Financial Implications of Quality Control Failures

Quality control failures in battery production can lead to devastating financial consequences:

Potential Cost Breakdown

| Failure Type | Estimated Cost Range | Potential Impact |

|---|---|---|

| Batch Recall | £500,000 - £5,000,000 | Complete production batch replacement |

| Performance Litigation | £1,000,000 - £10,000,000 | Legal claims from end-users or commercial clients |

| Reputation Damage | Immeasurable | Long-term brand trust erosion |

Comprehensive Quality Control Failure Insurance: What It Covers

A robust quality control failure insurance policy for battery manufacturers should encompass multiple protection layers:

Core Coverage Components

- Product Liability Protection

Shields manufacturers from financial repercussions of battery failures causing damage to end-user equipment or infrastructure.

- Recall Expense Coverage

Comprehensive financial support for complete or partial production batch recalls, including logistics, replacement, and communication costs.

- Business Interruption Insurance

Provides financial stability during production halts necessitated by quality control investigations or mandatory improvements.

- Regulatory Compliance Protection

Coverage for fines, penalties, and mandatory upgrades resulting from quality control non-compliance with international standards.

Proactive Risk Mitigation Strategies

While insurance provides crucial financial protection, manufacturers must implement comprehensive risk management protocols:

Recommended Risk Management Approaches

- Implement ISO 9001:2015 quality management standards

- Develop rigorous multi-stage testing protocols

- Maintain detailed production and testing documentation

- Invest in continuous employee training

- Utilize advanced statistical process control techniques

Emerging Trends in Battery Quality Control

The battery manufacturing landscape is continuously evolving, presenting new quality control challenges and opportunities:

Future-Focused Considerations

Technological Advancements

AI-driven predictive quality control, real-time performance monitoring, and advanced machine learning algorithms are revolutionizing defect detection and prevention.

Sustainability Impact

Increasing emphasis on sustainable battery production requires more sophisticated quality control mechanisms to ensure environmental compliance and performance longevity.

Securing Your Battery Manufacturing Future

Quality control failure insurance is no longer an optional safeguard but a critical strategic investment. By understanding risks, implementing comprehensive insurance coverage, and maintaining proactive quality management, battery manufacturers can navigate an increasingly complex technological landscape.

Next Steps

Consult with Insure24's specialized commercial insurance experts to develop a tailored quality control failure insurance strategy for your battery production operations.

0330 127 2333

0330 127 2333