Navigating Health and Safety Risks in Battery Production: A Comprehensive Guide

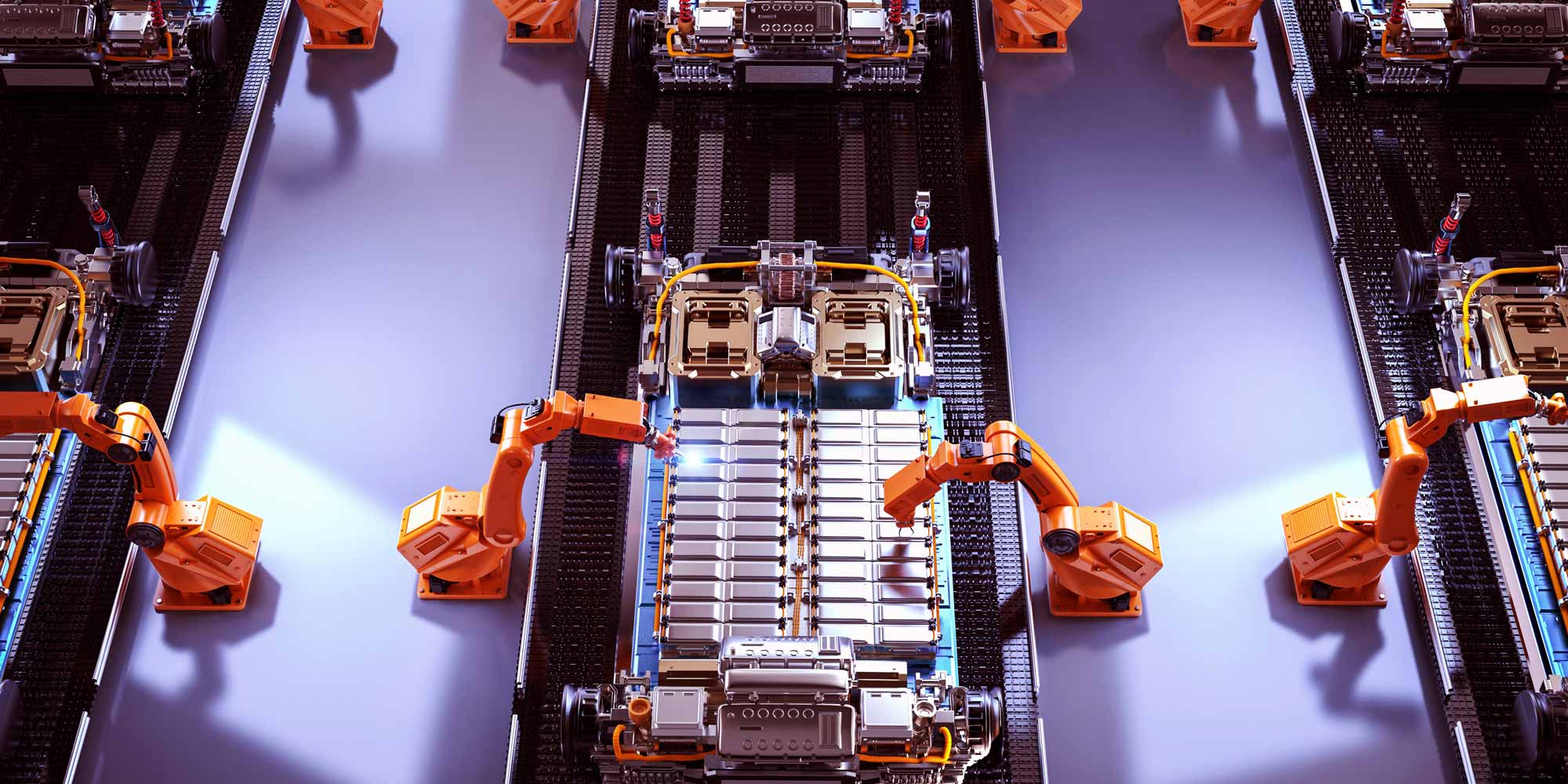

The battery production industry stands at the forefront of technological innovation, powering everything from electric vehicles to renewable energy storage. However, this critical sector comes with a complex landscape of health and safety risks that demand meticulous attention and strategic risk management.

Chemical Hazards: The Invisible Threat

Battery production involves handling a complex array of chemicals that pose significant health risks. Understanding and mitigating these risks is crucial for maintaining a safe working environment.

Lithium-Ion Battery Chemical Risks

- Electrolyte Exposure: Lithium-ion batteries contain volatile organic solvents that can cause respiratory irritation, skin burns, and potential long-term health effects.

- Heavy Metal Contamination: Batteries often contain cobalt, nickel, and manganese, which can cause neurological damage and respiratory issues with prolonged exposure.

- Toxic Gas Generation: During manufacturing and potential battery failures, toxic gases like hydrogen fluoride and phosphoryl fluoride can be released.

Risk Mitigation Strategies

- Implement comprehensive chemical handling protocols

- Provide advanced personal protective equipment (PPE)

- Establish robust ventilation systems

- Conduct regular health monitoring for workers

Electrical Risks: Managing High-Voltage Challenges

Battery production involves working with high-voltage systems that present significant electrical hazards. Understanding these risks is paramount to preventing accidents and ensuring worker safety.

Primary Electrical Risks

- Electrical Shock: High-voltage battery components can deliver fatal electrical currents

- Arc Flash Incidents: Potential for explosive electrical discharges causing severe burns

- Short Circuit Risks: Potential for rapid energy release and thermal runaway

Comprehensive Safety Protocols

- Mandatory electrical safety training

- Use of arc-rated protective clothing

- Regular equipment maintenance and testing

- Strict adherence to electrical work permit systems

Ergonomic Risks: Protecting Workers from Physical Strain

Battery production involves repetitive tasks and complex manufacturing processes that can lead to significant ergonomic challenges and potential long-term health issues.

Common Ergonomic Risks

- Repetitive Motion Injuries: Continuous assembly line work can cause musculoskeletal disorders

- Heavy Lifting: Battery components and equipment can cause significant physical strain

- Prolonged Standing: Extended periods of static postures lead to circulatory and muscular problems

Ergonomic Intervention Strategies

- Implement job rotation programs

- Invest in ergonomic workstations

- Provide regular breaks and stretching programs

- Use mechanical assistance for heavy lifting

Fire and Explosion Risks: Managing Battery Volatility

Battery production facilities face unique fire and explosion risks due to the volatile nature of battery materials and manufacturing processes.

Critical Fire Hazards

- Thermal Runaway: Uncontrolled temperature increase leading to potential battery combustion

- Flammable Electrolyte: Organic solvents used in battery production are highly flammable

- Dust Explosion Risks: Metallic powders used in production can create explosive atmospheres

Fire Prevention and Mitigation

- Advanced fire suppression systems

- Strict material storage protocols

- Regular fire safety training

- Comprehensive emergency response planning

Environmental Monitoring and Air Quality Management

Battery production facilities must implement rigorous environmental monitoring to protect worker health and comply with regulatory standards.

Key Monitoring Parameters

- Volatile organic compound (VOC) levels

- Heavy metal particulate concentrations

- Toxic gas emission tracking

- Ambient temperature and humidity

Training and Compliance: The Foundation of Safety

Comprehensive training and strict adherence to safety regulations are non-negotiable in battery production environments.

Essential Training Components

- Chemical handling and emergency response

- Electrical safety procedures

- Personal protective equipment usage

- Emergency evacuation protocols

- First aid and incident reporting

Insurance Considerations for Battery Production Facilities

Given the complex risk landscape, specialized insurance coverage is crucial for battery production businesses.

Recommended Insurance Coverage

- Comprehensive General Liability

- Product Liability Insurance

- Professional Indemnity Coverage

- Cyber Insurance for Technology Risks

- Business Interruption Protection

Conclusion: A Proactive Approach to Safety

Battery production represents a critical intersection of technological innovation and complex risk management. By understanding and systematically addressing these unique health and safety challenges, manufacturers can create safer, more efficient production environments.

0330 127 2333

0330 127 2333